Hisson Plastic Machinery Co., Ltd.

Sales Office:

What is the injection molding machine used for? Injection molding machine is used to mold plastic products, nylon products and other automatic equipment. The working process of the factory direct injection molding machine includes pressure lifting, heating, mold clamping, injection molding, pressure holding, and mold opening.

【component】

General injection molding machines include injection devices, mold clamping devices, hydraulic systems and electrical control systems.

【Hydraulic system and electrical control system】

It is a power and control system that guarantees that the injection molding machine can work accurately and effectively according to the predetermined requirements of the process (such as pressure, speed, temperature, time, etc.) and the action program.

【Injection device】

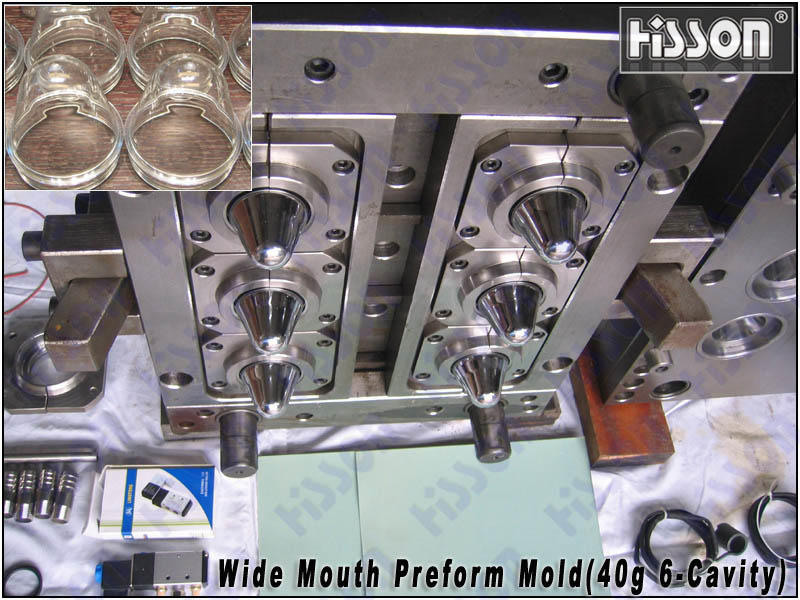

Its main function is to plasticize the plastic uniformly into a molten state, and to inject the molten material into the pet preform mold with sufficient pressure and speed. It is mainly composed of plasticized parts (barrel, screw or plunger, nozzle, etc.), hopper, screw drive (oil motor, etc.), injection cylinder, injection seat moving cylinder, etc.

【Clamping device】

It is a component that guarantees the reliable closing of the forming mold and realizes the opening and closing of the mold and taking out the product. Since the melt is injected into the mold cavity at a high pressure, in order to lock the mold without causing flash or affecting the quality of the product, it is necessary to apply sufficient locking force (ie clamping force) to the mold. The mold clamping device mainly includes a fixed mold plate, a movable mold plate, a rear wall panel, a tie rod for connecting front and rear mold plates, a mold clamping cylinder, an ejection cylinder, and a mold adjustment device.

The rise of the plastics industry has driven the growth of vertical injection molding machines. The total production value of vertical injection molding machines is refreshing every year. Under what circumstances must vertical injection molding machines be used?

In the plastics processing industry, vertical injection molding machines are the most used injection molding equipment. The output of vertical injection products accounts for more than 30% of the total plastic products. It is characterized by easy production automation, short production cycle, and strong adaptability. , High-end production power.

Vertical injection molding machine is a very important injection molding equipment, horizontal injection molding machine supplier, has more than 50 years of development history. The vertical injection molding machine can heat the plastic and apply high pressure to the molten plastic so that it can be injected to fill the mold cavity to make various shapes of plastic products.

Plastic products are a very widely used production material. As the core production technology for plastic products, factory direct sales vertical injection molding machines have been widely used in production and life. Vertical injection molding machines are used in transportation, building materials, agriculture, catering, and national defense. Fields such as construction are playing an increasingly important role.

Hisson Plastic Machinery provides customers with high-quality injection molding machine products, with superb technology and complete equipment system, horizontal injection molding machine supplier, huge production capacity, high cost performance, it is your best choice for the brand of injection molding machine.

Copyright © 2019 Hisson Plastic Machinery Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.