Hisson Plastic Machinery Co., Ltd.

Sales Office:

Blow molding plastic is a procedure where hollow 3D articles are produced using various kinds of thermoplastic materials. These materials are usually available in powder or granular form. The simplest blow molded tool has two parts, which are closed and consist of a cavity inside.

A plasticizing cylinder is used by blow molding manufacturers for softening the granular or powder materials, which are then thrust into a parison (vertical tube). An open mold surrounds this parison that is later closed. Thus, the bottom end is sealed effectively and then, the other end is used for sealing it in a pneumatic manner.

The mold’s geometry and the parison’s size determine what the distribution, wall thickness and other dimensions of the manufactured article would be. This makes them important factors, along with the die design, which is affected, by backpressure, land length, melt compression and melt flow pattern. For producing bottles that have uniformity in wall thickness, the wall thickness of the parison is controlled using various pre-stated steps by manufacturers.

Blow molding is an extremely affordable, sustainable, and versatile process, but with any manufacturing method, it has its benefits and drawbacks. While the types of blow molding vary, the benefits of this revolutionary technology are universal.

Advantages: Because of lower pressure, the mold costs in extrusion blow molding are lower as compared to injection molding and the machinery costs are low as well. Also, it’s easy to mold external threads. Making open-ended parts that are large can be done by splitting open a closed molding.

Cost is a big factor in any manufacturing, especially a large-scale, industrial venture. Blow molding is typically quite inexpensive compared to other fabrication methods, making it completely customizable and scalable to the client’s needs. Furthermore, it simplifies applying external threads, improving overall product quality and consistency.

Blow molding is also a relatively fast manufacturing solution. Professional grade injection or pet bottle blow molding machine is capable of producing huge quantities of finished products, and can run for a virtually indefinite amount of time.

The versatility of blow molding is a big advantage, and a reason it revolutionized a number of industries. The diverse number of customizable bottles, containers, and other products makes blow molding especially attractive to food suppliers, medical and pharmaceutical companies, and more.

Disadvantages: As the diameter of the mold increases, the corners and areas with the thinnest walls have close tolerance. Plus, extrusion molding has longer cooling times than injection molding. Also, it is not possible to mold in holes except after the molding.

One disadvantage of blow molding plastic is the fact that you’re working with plastic, a petroleum product. That said, many polymers used are recyclable, and the industry is hard at work finding more durable, versatile, and sustainable materials.

Another disadvantage is the limitations in the design of blow molded products; hollowed out custom plastic bottles and other similar containers are usually the best fit for this process.

As you can see, the benefits of pet blow molding outweigh the disadvantages as long as the product you have in mind is a good fit for this process. Blow molding produces durable, inexpensive products in large quantities, and those products are often recyclable.

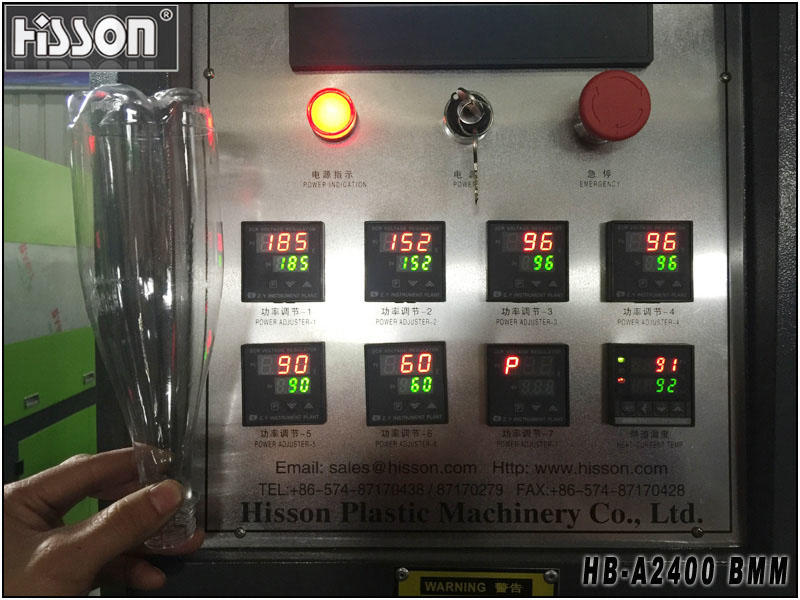

Hisson Plastic Machinery Co., Ltd. is a manufacturer of high-performance plastic injection molding machines and PET bottle blow molding machines.

In PET bottle field, we have abundant experience, we have special PET preform injection molding machine, semiauto and automatic PET bottle stretch blow molding machine, we have 2-cavity, 4-cavity and 6-cavity automatic PET bottle blow molding machines.

With cooperation with manufacturers of high quality preform mold, blow mold, cap mold and auxiliary equipment, we provide complete production line for PET preform injection and bottle blowing.

We provide 2D and 3D design service for PET preforms and PET bottles, according to samples, design draft or only idea.

Copyright © 2019 Hisson Plastic Machinery Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.