Hisson Plastic Machinery Co., Ltd.

Sales Office:

1. Injection system: The injection system is one of the main components of the injection molding machine

2. Mold clamping system

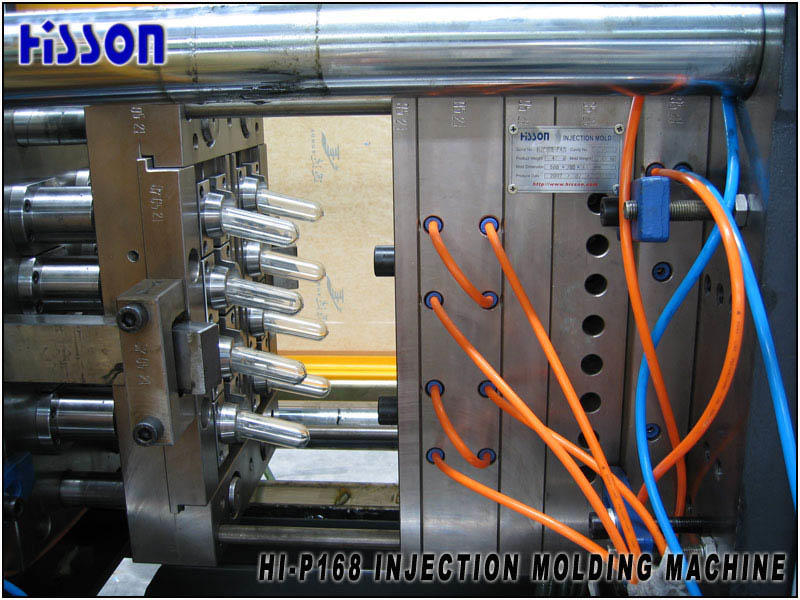

The function of the mold clamping system: The function of the mold clamping system is to ensure that the mold is closed, opened and the product is ejected. At the same time, after the mold is closed, the mold is provided with sufficient clamping force to resist the cavity pressure generated by the molten plastic entering the mold cavity, preventing the mold from opening and causing the undesirable status of the product.

Composition of the mold clamping system: The mold clamping system is mainly composed of a mold clamping device, a machine twist, a mold adjustment mechanism, an ejection mechanism, front and rear fixed templates, a movable template, a mold clamping cylinder and a safety protection mechanism.

3. Hydraulic system

The function of the hydraulic transmission system is to realize the plastic injection moulding machine to provide power according to the various actions required by the process, and to meet the requirements of the pressure, speed, temperature and other parts of the injection molding machine. It is mainly composed of various hydraulic components and hydraulic auxiliary components, in which the oil pump and motor are the power source of the injection molding machine. Various valves control oil pressure and flow to meet the requirements of the injection molding process.

1. The effect of workpiece surface condition on polishing process

During the crushing process of steel machining, the surface layer will be damaged by heat, internal stress or other factors. Improper cutting parameters will affect the polishing effect. Therefore, high-speed CNC finishing is required, and the cutting amount is controlled at 0.05mm ~ 0.07mm.

2. The effect of different hardness on the polishing process

The increased hardness increases the difficulty of grinding, but the roughness after polishing decreases. As the hardness increases, the polishing time required to achieve a lower roughness increases accordingly. At the same time, the hardness increases and the possibility of excessive polishing decreases accordingly

The surface after EDM is more difficult to grind than the surface after ordinary mechanical processing or heat treatment. Therefore, before the end of EDM, precision quasi-EDM should be used for trimming, otherwise the surface will form a hardened thin layer. If the electric spark finishing standards are not properly selected, the depth of the heat-affected layer can be up to 0.4 mm.

The hardness of the hardened thin layer is higher than the hardness of the substrate and must be removed. Therefore, it is better to add a rough grinding process to completely remove the damaged surface layer to form an average rough metal surface, which provides a good basis for polishing.

Copyright © 2019 Hisson Plastic Machinery Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.