Hisson Plastic Machinery Co., Ltd.

Sales Office:

What are the advantages of the standard vertical injection molding machine? The so-called standard vertical injection molding machine is the most basic vertical injection molding machine without any optional equipment.

1. Each plastic part cavity can be taken out by a simple manipulator, which is conducive to precision molding.

2. It is easy to ensure the resin fluidity in the mold and the consistency of mold temperature distribution.

3. In small batch trial production, the mold structure is simple, low cost, and easy to unload.

4. The belt conveyor is easy to be installed in the middle of the mold, which is convenient for automatic molding production.

5. Equipped with rotating table, movable table and inclined table, it is easy to realize insert molding and in-mold combination molding.

6. Generally, the mold clamping device is surrounded by an open type, which is easy to configure various automatic devices, and is suitable for automatic molding of complex and delicate products.

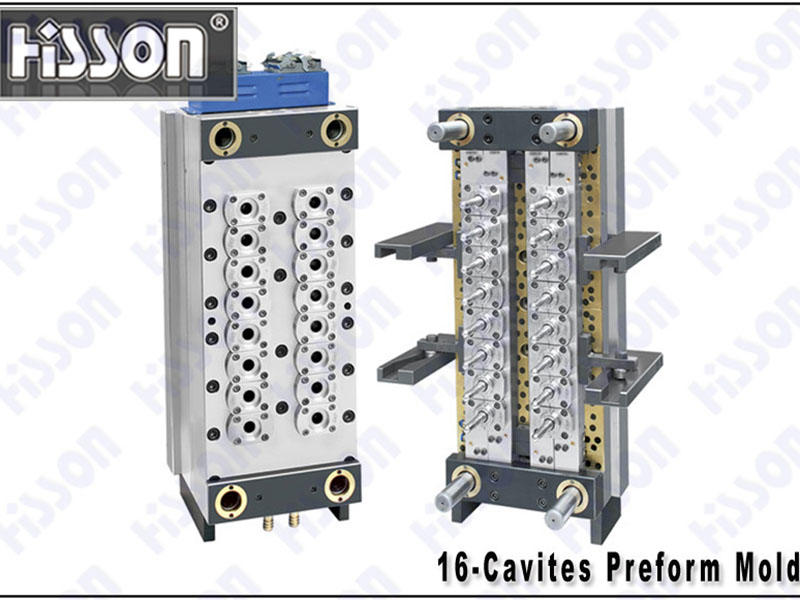

7. The injection device and the mold clamping device are on the same vertical centerline, and the pet preform mold is opened and closed in the up and down direction. Its floor space is only about half of that of a horizontal machine, so it is about twice as productive as the floor space.

8. Easy to realize insert molding. Because the surface of the mold faces upwards, it is easy to insert and position the insert. If the lower template is fixed and the upper template is movable, combined with a belt conveyor and a manipulator, fully automatic insert molding can be easily realized.

9. The weight of the mold is supported by the horizontal template to open and close up and down, and the phenomenon that the template cannot be opened and closed due to the gravity of the injection mold like a horizontal machine will not occur. It is conducive to maintaining the precision of machinery and molds.

Most of the vertical injection molding machines are classified according to their functions. For example, the disc machine is the lock template part is the disc can rotate, we call it the disc machine. The skateboard machine is that the lock template part is the skateboard machine, followed by some optional equipment such as servo motors, mechanical arms, and automation devices. The standard machine is the foundation, add these things on these foundations to become another type.

Copyright © 2019 Hisson Plastic Machinery Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.